UV curing 3D printing technology is a computer-controlled process that selectively solidifies the photosensitive resin layer by layer using a UV beam, and controls the displacement of the platform in the z-axis direction. The next layer of photosensitive resin solidifies on top of the previous layer, thereby completing the production of 3D printed parts. Among them, the research and development of photosensitive resin is the key to the application of photo-curing molding technology. UV cured 3D printing uses a radiation source to irradiate a liquid photosensitive resin, triggering a chain reaction that links a large number of small molecule monomers or prepolymers together to form a highly cross-linked polymer.

Application Areas

UV cured 3D printing has high photosensitivity, low energy consumption, low cost, high accuracy, smooth surface and good repeatability. It has been widely used in aerospace, automotive, mold manufacturing, jewelry design and medical fields. Let’s see together what breakthroughs there are for below industries.

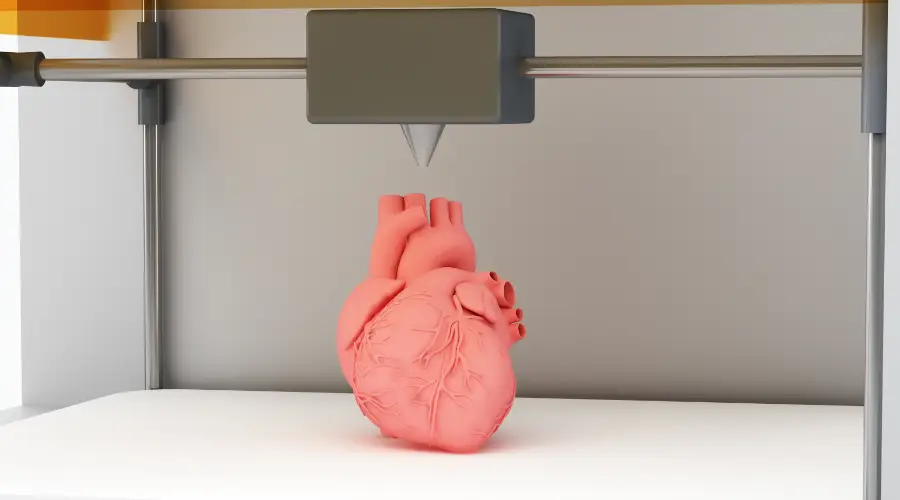

1. Medical Orthopedic Field

Researchers used CT technology to scan and obtain the internal structure of the patient's skull, and successfully printed a skull model using a 3D printer. With the development of 3D printing technology, it has been widely used in many countries in medical fields such as neurosurgery, dental implantation, orthopedics and the manufacturing of prostheses, as shown in below Figure. Data shows that with the assistance of 3D printing technology, doctors can improve their diagnostic accuracy by 28%, increase operational accuracy by 36%, and shorten surgical time by 18%.

2. Manufacturing Field

3D printing technology is currently changing manufacturing and production technologies, such as creating lightweight and cost saving components in the aviation and automotive industry, organ printing in tissue engineering, the construction industry, electronic products and sensors, shape memory materials, and more. In precision casting, the three-dimensional resin mold produced by 3D printing technology can replace wax molds for shell formation. The resin mold is removed during shell baking to obtain a hollow shell, which can be used to cast high-precision models. The obtained alloy castings with good surface smoothness can be directly used as the cavity of injection molds, shortening the molding process.

3. Anime Derivative Product Domain

In recent years, with the rapid development of the anime figurine market and anime idol DIY, more and more anime institutions and individual enthusiasts are using 3D printing technology to quickly and three-dimensional display their unique creative designs. As shown in figure below, the process of transforming from ideological thinking to physical 3D models has been achieved, which not only meets the needs of anime enthusiasts, but also promotes the transformation of the anime industry.